Upcycling Element Panels

3. June 2020

Angry Face goes Powder Coating

22. December 2020Refurbishing Tangent Element Panels

Hi everyone,

it’s been a while since we last posted something – but we’ve been pretty busy preparing a new product – more details soon to follow!

In the meanwhile, we thought we’d share some insights about refurbishing used Element panels. As you all know, they have a soft coating, which can get sticky after a while.

Well, you can do something about it. The easiest way of dealing with sticky softcoating is to apply some talkum powder – or simply baby powder (smells nicer) onto the surface. The powder sucks up the moisture and the panel feels super nice and smooth again. The downside obviously is, that it’s only temporary and that it does not look particularly nice (although that ship might have sailed anyways, if you have to apply it in the first place). If you’re still interested in giving this a try, find the article here.

There are 3 other options you can pursue (or ask us to pursue for you ;-).

All of them require that the softcoating is stripped off first, which means you have to take the panel apart completely and wash down the softcoating, using Acetone, Isopropyl alcohol or some sort of sticker removal. Next you can go any of these ways: Foil, lacquer – or if you really want it to last: sandblast and anodize it.

Foiling is a cheap and quick way of giving your panels a nice, new look. Plus, it feels nice and is fairly sustainable.

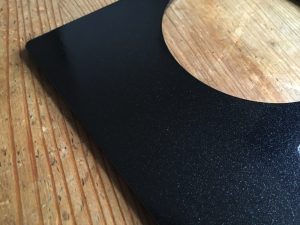

If you want to give this a try – here’s the article on how to get it done. See the below pictures to get an idea of what it could look like:

Lacquering and anodizing are certainly the best ways to even up your panels in value. If you want to go the lacquering route, talk to your local car lacquerer to do the job.

It is fairly cost efficient and will look really nice afterwards. Have some though on whether you want a glossy, or matte finish, before taking the panel to the lacquerer. Below you can see three examples: Grey Hammerschlag, Silver Hammerschlag and Black metallic finish.

Now anodizing is the most interesting and most sustainable option. However, it also costs quite some buck and you need to make sure that the steel posts underneath the fascias

are protected – otherwise, the anodizing bath will destroy them and make the panel fascias unusable. The fascias also need to be sandblasted (or alternatively brushed, or even polished) before they can be anodized. See below three examples in silver, space grey and black anodize finish:

I hope these examples gave you some inspiration on how to shine up your panels again. If you want us to take care of your panels in any such way, don’t hesitate to contact us!

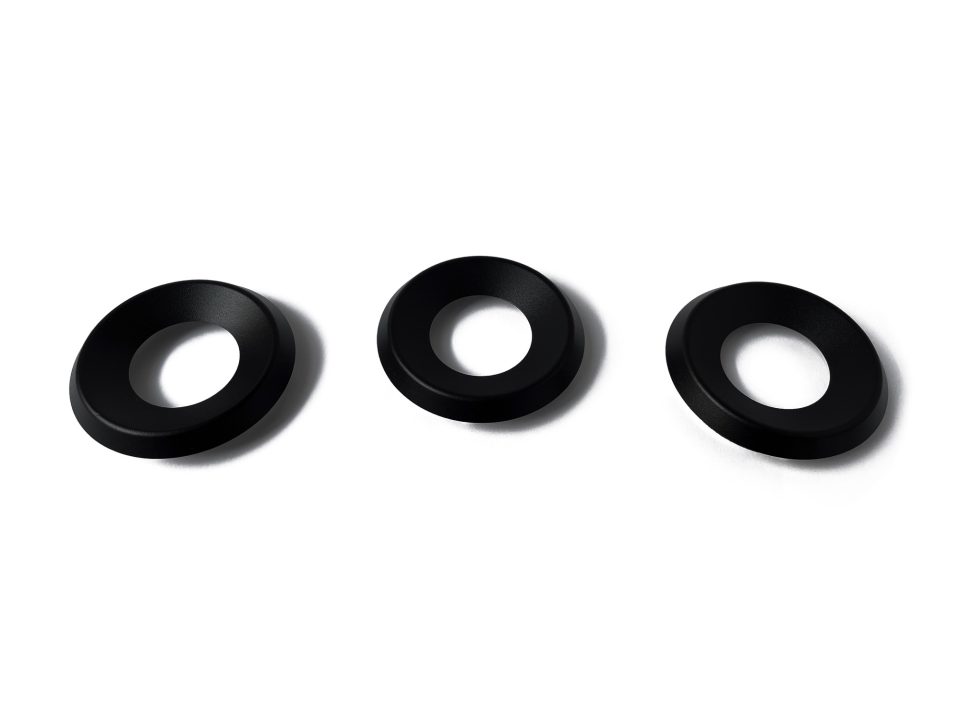

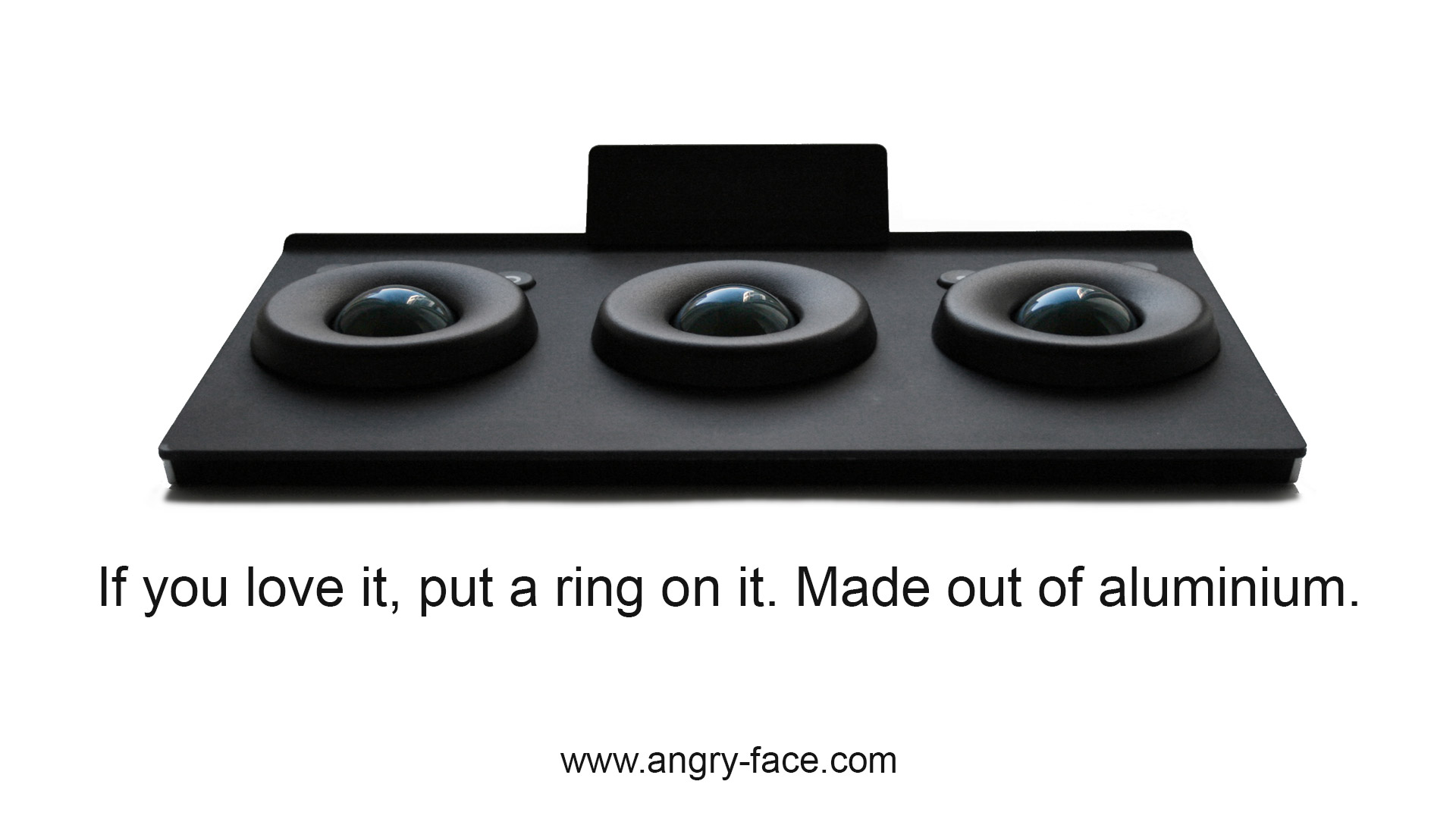

And of course, if you want to give your panel the final touch, check out our anodized aluminium rings and dark petrol-metallic trackerballs for the Elements below this article!

Cheers,

Mazze

-

Über-Bundle: Black Aluminium Rings + Dark Petrol-metallic Trackerballs + Dust Cover

265,00 € (excl. VAT) -

Black Metal Rings for the Tangent Element panel (set of 4)

170,00 € (excl. VAT) -

Black Metal Rings for FilmLight (set of 3)

250,00 € (excl. VAT) -

Dark Petrol-metallic Tangent Element Trackerball (set of 4)

65,00 € (excl. VAT) -

Angry Face Element Refurbish

380,00 € – 670,00 € (excl. VAT) -

Element Panel Foam Inserts incl. Peli Case 1510

450,00 € (excl. VAT) -

Element Panel Foam Inserts for Peli Case 1510

210,00 € (excl. VAT) -

Element Panel Dust Cover

60,00 € (excl. VAT)